Swiss sustainable lightweighting company Bcomp says it is excited to announce new bus air-conditioning covers made by Eberspächer using its natural fibre composite technology, helping the push towards the use of more sustainable materials in mass transport applications and closely follows the firm’s entry into large-scale production of automotive interior parts.

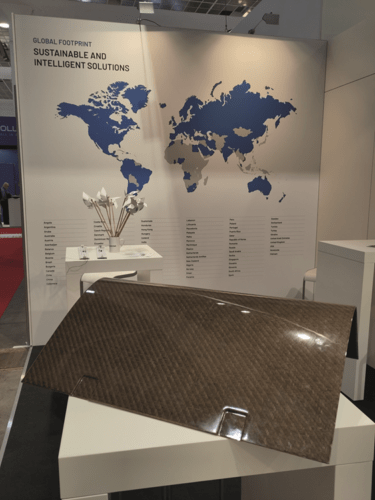

Exhibited at Busworld Europe, Eberspächer manufactured the prototype panels using Bcomp’s ampliTex technical fabric to gauge interest among manufacturers. The composite panels use a vynilester resin infusion with an in-mould transparent gelcoat finish. Based on manufacturer or end customer interest during the event, a trial phase is planned to follow, with similar panels installed in buses operating in diverse environmental conditions including the extreme climates in winter and summer testing. Successful performance evaluations will pave the way for series approval and full-scale manufacturing.

The collaboration was initiated by an Eberspächer student proof-of-concept project from the Technical School for Wood Technology in Stuttgart. The challenge was to find an environmentally responsible alternative to glass-fibre-reinforced plastic for bus air-conditioning covers, and flax-based natural fibre composites emerged as the preferred material, of which Bcomp is a specialist.

Its ampliTex technical fabric has been used in body panels for motorsport applications and can already be found as an optional interior material on the new Volvo EX30 car. Paolo Dassi, Marine and Industry Manager at Bcomp, commented: “This project with Eberspächer marks an exciting new chapter in our journey. Mass transport applications like this innovative bus air-conditioning cover reinforce our technologies’ potential to replace conventional materials at scale. It also signals our continued growth and expansion into critical markets. As industries increasingly seek out sustainable materials, we are ready to meet the demand with our flax-based composites that offer lightweighting performance without environmental compromise.”