Good preventative maintenance is essential in winter conditions and can save costs in the long-run, Imperial Engineering reminds operators

As the winter season gets underway, PSV engineers and technicians will be prepared for the maintenance challenges of cold, wet weather. This year has seen significant rainfall, with record-breaking rain in some areas, causing debris to be washed onto roads. Whilst buses are intentionally designed to sit low to the ground to ensure accessibility, this also makes under-chassis systems and the braking system in particular, susceptible to problems caused by the ingress of water and dirt.

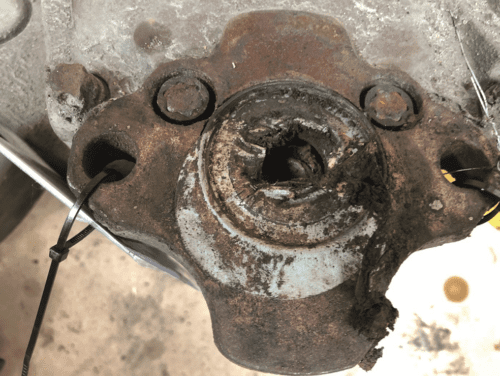

Regardless of powertrain: diesel, hybrid or electric, all of today’s buses are equipped with an electronic braking system (EBS), which combines anti-lock braking (ABS) and traction control into a single system, that utilises compressed air as the energy source to power the foundation brake assembly on each wheel. These comprise of a brake disc (rotor), brake pads (friction material) and calliper, as well as a wheel speed sensor to relay information to the EBS control unit.

As a specialist OEM parts distributor serving bus and coach fleets throughout the UK, Imperial Engineering has seen growth in demand for replacement brake system components. This is despite the fact that specific parts, such as callipers, are expected to last the typical vehicle service life when properly inspected and maintained in accordance with the original equipment manufacturer’s recommendations. Maintaining service life also requires that under-chassis inspections take place regularly and the braking and compressed air systems are well maintained.

Aware that premature failures are causing operators unnecessary expenditure, Imperial Engineering has investigated brake system component failure in detail and has found a number of potential brake system problem areas, and recommends that these are checked and rectified during vehicle inspection and maintenance, so that components are more likely to reach their intended service life.

Compressed air system

[…]By subscribing you will benefit from:

- Operator & Supplier Profiles

- Face-to-Face Interviews

- Lastest News

- Test Drives and Reviews

- Legal Updates

- Route Focus

- Industry Insider Opinions

- Passenger Perspective

- Vehicle Launches

- and much more!