UK-based Advanced Electric Machines (AEM), which specialises in sustainable electric traction for the motor industry, is to supply its HDSRM300 motor for an new retrofit kinetic energy recovery system (KERS) solution.

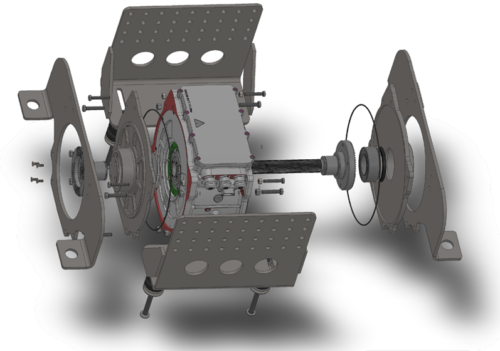

Designed and built for commercial vehicles, coaches and buses, the system brings together AEM electric motors with ultracapacitors and heavy-duty power electronics to create a bolt-in, retrofit KERS system that can hybridise existing combustion vehicles.

AEM says its kit does not require permanent chassis modifications and can help fleet operators to save money and the environment by recovering energy that would otherwise be wasted during braking and using it to assist the engine during acceleration. The company says the system has been shown to reduce fuel consumption and CO2 output by up 28%, and overall emissions (NOx, PMs and brake particulate matter) by up to 80% in its development vehicles.

The firm adds that its electric motors use no rare-earth elements in their construction, helping to make the overall system easier to recycle and more sustainable in its design.

AEM explains that for drivers, there is also the benefit of additional power supplied by the ultracapacitors under acceleration, which means that a bus can gain speed more quickly.

AEM Business Development Consultant Richard Lidstone-Scott said: “Efficiency is fundamental to the success of bus operators. The KERS kit is a fast, flexible and fuel-agnostic means of achieving bus hybridisation, reducing fuel consumption and emissions, while pushing businesses to achieve the lowest overall driving costs. There’s no need for new charging infrastructure, the system can last for more than a decade in service, and it can be removed and refitted to other vehicles. It’s a no-brainer for operators looking to maximise their margins by reducing fleet costs.”

Advanced Electric Machines says it has a vision is to design and build the world’s most sustainable EV motors for the global automotive and transport sectors. Based in the North East of England, the company was founded in 2017, when it was spun out from Newcastle University’s electric motor research team, led by AEM’s CEO James Widmer, and CTO Andy Steven.