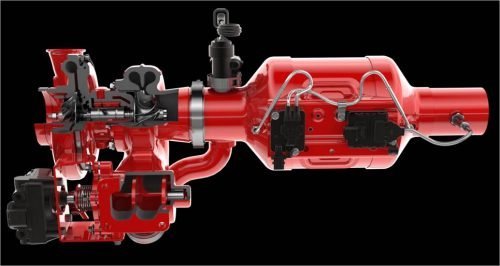

Cummins Inc. has unveiled its latest research and development investment in new oil sealing technology for Holset turbochargers.

Matthew Purdey, Group Leader in Subsystems Engineering at Cummins Turbo Technologies, presented the findings from his paper on new sealing technology, entitled ‘Development of an Improved Turbocharger Dynamic Seal,’ at the Supercharging Conference in Dresden, Germany in September.

“With customers demanding smaller engines with greater power density, along with lower emissions, the turbocharger remains one of the most critical components on a vehicle driveline,” said Brett Fathauer, Executive Director of Research and Engineering at Cummins Turbo Technologies.

“Cummins is dedicated to delivering excellence to customers through continuous innovative ways to improve turbocharger performance and by recruiting best-in-class engineers.”

Oil leakage from a turbocharger leads to reductions in performance and emission non-compliance. Cummins’ latest innovation reduces these risks through the development of a more robust sealing system. The paper highlights some of the other elements that were taken into consideration when the sealing technology was in the research and development stages. Some key factors included:

- Turbocharger Efficiency: The non-contact seal system design enables good transient response by not introducing additional friction to the rotor system. The technology also allows optimisation of the compressor stage diffuser and wheel line up for efficiency gains;

- High Bypass: There is a need to drive closer integration between the aftertreatment and turbocharger to optimise system-level performance. The concept Integrated System, featuring bypass technology, is one of the research methods Cummins is investing in to achieve better system integration for turbocharger efficiencies and thermal management improvements. This method of exhaust gas bypass requires oil sealing technology to be robust as a reduction in pressure behind the compressor wheel may occur, which could lead to potential oil leakages.

Read more news at: cbwmagazine.com/category/news