Jonathan Taylor continues his report from Gothenburg and Volvo’s new World of Volvo exhibition and conference centre

Last month’s ‘World of Volvo’ event in Gothenburg brought together operators from across the world making it a truly global gathering of the industry. After the spectacular reveal and launch of the Volvo BZR electromobility platform, there was a packed second day of presentations, discussions and even some light-hearted gaming. Volvo used the day to bring all the attendees up to date with its latest thinking on a range of subjects.

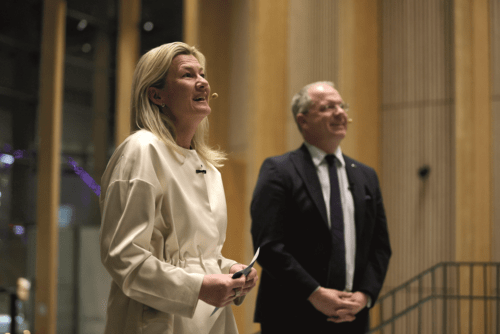

Volvo Buses President Anna Westerberg started the proceedings with a short talk in which she gave us the mantra ‘Partnership is the new Leadership.’ She emphasised that, with the big changes taking place in how vehicles are powered and the drive for net zero, Volvo, even as a global business, could not do everything itself. It needed, she said, its strong worldwide partnerships with many other large and small businesses to successfully make the leap to what will be the different technical world of one or two decades ahead.

The first session was entitled ‘Sustainability Beyond Emissions.’ In this session, Volvo’s Chief Sustainability Officer Karin Svensson gave us the overview of how the Swedish company is thinking and acting.

Volvo is committed to all its own fleets becoming fossil free by 2040 and aiming to have all its customer fleets fossil free by 2050. Anna went on to tell us that Volvo will always play fair and is concerned with taking action beyond the words. She said: “Electrification, of course, contributes to

less CO2.”

For early large battery technology that may not have been true, but Volvo is clear that this is a complex subject requiring solutions throughout the sourcing, manufacture, use and afterlife use of every component in the supply chain. It wants to be first mover in building sustainable supply systems. This means that Volvo, with its partners, is integrating sustainability into everything it does. It is addressing the entire electrification ‘ecosystem.’

Volvo gave examples of ecosystem partnership working with the International Association of Public Transport (UITP: Union Internationale des Transports Publics) and Keolis which, although mainly a light rail operator in the UK, operates a fleet of 25,000 buses worldwide.

[wlm_nonmember][…]By subscribing you will benefit from:

- Operator & Supplier Profiles

- Face-to-Face Interviews

- Lastest News

- Test Drives and Reviews

- Legal Updates

- Route Focus

- Industry Insider Opinions

- Passenger Perspective

- Vehicle Launches

- and much more!

Sustainability is now built in to every Volvo component and product. The company tries to design-in ‘second-life’ uses for all its products. The Volvo purchasing department is central to ensuring sustainability throughout the production system through a supply partner code of conduct.

The full cycle is design – supply – manufacture – users – end of life – re-use.

In terms of performance and targets, Volvo Sweden now has zero waste. Volvo Global has reduced emissions from bus chassis manufacture by 90% in the last four years.

Better batteries

The second session, was titled ‘Volvo Buses and the battery value chain.’ Elisabeth Larsson of Volvo Energy (the newest business area in Volvo) told us that she is focused on the electrification infrastructure and the battery value chain. Looking at batteries specifically, she explained that the main goal is to make batteries last as long as possible for their first ‘life’ of providing traction power.

After that primary life, batteries can be refurbished or fully re-manufactured again for bus use. Beyond that, they can be re-purposed for another use giving further value. For example, they can become an energy storage system for solar panels on a depot roof. The load on a battery with this use is much more gentle than when used for traction power and can give batteries another 10 years of life post-bus. Volvo is thinking of batteries as an asset to generate revenue.

In terms of design, you will not be surprised to hear that safety is paramount for Volvo and is built in to its battery designs. The BZR platform batteries are housed in a crash protection cage. And at the end of their life, Volvo will collect and recycle its batteries.

Fredrik Agelen and Jorgen Gustafsson told us about Volvo’s new battery plant being constructed at Mariestad in Sweden just off the main E20 road link between Gothenburg and Stockholm. Mariestad is located on the shores of Lake Vanern, Sweden’s largest freshwater lake. Vanern has a surface area of 2,180 square miles and is the largest lake in Europe outside Russia. By comparison, the largest surface area lake in the UK is Lough Neagh in Northern Ireland at just 148 square miles. Water from Vanern is used for cooling in the battery manufacturing plant.

The huge site will employ around 3,000 people and produce batteries for the Scandinavian and rest-of-Europe markets. There will be a separate plant for America. Demonstrating its commitment to the environment, Volvo has relocated the wildlife population of the construction site to a new purpose-built area of four large ponds and landscaped areas. Among the wildlife relocated have been 13,000 salamanders, plus frogs and dragonflies. The site is having zero-emission commuting options designed in for all the new local employees.

The third session titled ‘Volvo Group and the digital transformation’ was presented by Rebecka Granqvist, Chief Digital Officer at Volvo Buses. This was more of a run through the possibilities of digitisation related to the bus industry, than a here and now report of actions already happening.

Rebecka talked about a world in which buses are talking to each other, and learning as they travel, in order to maximise service efficiency. She imagined us having personalised AI bots, located on our watches, finding super-efficient travel options and acting as a kind of co-pilot on journeys.

As CBW readers will already know, my view is that public travel will likely undergo massive disruption and move from an operator/provider model to a customer demand model, with operators merging services to provide what customers want as part of a door to door service. We will see what happens.

The fourth session was ‘Volvo Buses complete offer’ and presented by Emelie Agren and Carola Nilsson of Volvo Connected Solutions and Fredrik Bjorn from product development at Volvo Buses.

This was a run through the Volvo Blue, Silver and Gold maintenance packages which give operators their preferred service level with fixed monthly costs. We also heard about the new tech being developed to monitor vehicles sufficiently to avoid on-road breakdowns and optimise preventative maintenance.

Safety and autonomy

Next we had an animated demonstration of Volvo Safety Zone technology where vehicles can be pre-programmed to know when they arrive at a safety sensitive zone (e.g. a school) and automatically reduce speed to a pre-set level. This is actually in use successfully on 440 buses in Bogota, Colombia.

This session was followed by ‘Safety and autonomous driving – the path towards zero accidents.’ According to the World Health Organisation, nearly 1.2 million people die in road accidents annually. Having pioneered safety at the heart of vehicle design, Volvo is now moving on, aiming high, and has set itself a mission to reduce road accidents to zero. There is an understanding that this might be an impossible goal, but the drive to try to achieve it is yielding results.

Volvo is building in a range of safety systems which are integrated so they don’t distract the driver. There is front, short range assist which is scanning for people in front of the vehicle and scanning for queues or other slower vehicles ahead. There is adaptive cruise control and intelligent speed assistance (which recognises road signs). There is the driver alert system, the tyre pressure monitoring system and the lane-keeping support system. Volvo is building on all these features to develop vehicles which are alert and self-controlled enough to avoid having accidents or collisions with anyone or anything. It’s a big mission.

A central part of the drive for zero accidents is the creation of autonomous vehicles to take human error out of the equation. Volvo believes that, currently, truly autonomous vehicles can only operate in defined areas where there are few external ‘disturbances.’

This moved us on to ‘The future technology of the Volvo Group’ session led by Lars Stenqvist, Chief Technology Officer at Volvo Group and Mattias Rangeby, Chief Technology Officer at Volvo Buses. They gave us a future view of buses that can never hit anything because of the on-board tech. They showed us autonomous vehicles operating a limestone open cast mine in Norway. With that experience, they hope to move on to introduce autonomous vehicles to more complex environments.

Lars told us that Volvo Group invested €2.6bn in research and development in 2023. This investment is being used to develop common architecture and shared technology for its vehicles (with production economies and better parts availability as spin-off benefits). It is also being used to explore and harness the various possible ways of moving vehicles. Volvo still expects to be using internal combustion engines (ICE), but running on biofuel. Battery electric is its main thrust, and in production now, as well as fuel cell electric using hydrogen which is converted into electricity.

It sees huge potential with growing digitisation and AI and now has 1.6m connected Volvo vehicles worldwide which could potentially be monitored for that breakdown prevention service and other benefits. They admit that there are GDPR issues. We were shown a graphic illustrating the difference in the number of lines of software in a 2023 vehicle compared to various earlier years. The difference was startling; digitisation of everything is happening fast. It probably opens up opportunities we haven’t thought of yet.

Body partners

Next was a reminder, the session titled ‘Volvo and bodybuilders in partnership’ of how important the partner bodybuilders are for Volvo. An example was given by Jaime Verdu, Managing Director of Volvo Buses Spain/Portugal. He has 15 partner bodybuilders in the local market making everything from minibuses upwards. He said this gave operators the benefits of competitiveness, bodies matched to demand and faster delivery.

Karim Ghabbour, MD and President of body builder MCV told us how closely MCV has been working with Volvo on the BZR chassis. Talking about existing products, Karim said that deliveries into the UK in 2024 will double those of 2023. This is a close relationship that has developed over 15 years.

The final session was a panel discussion about ‘E-mobility in reality – learnings, reflections and outlook.’ The UK panellist was Sarah Boyd, CEO of Lothian Buses. Among other things, she gave us the practical view of being an operator during this rapidly-changing technical adjustment from carbon to zero-carbon. Only 10 years ago the focus was on clean air. Now it is not just on zero-emissions, but on zero carbon.

Things used to be simple, she said, with engineers buying and maintaining buses and schedulers doing the rest. But with electrification has come the need for focus on opportunity-charging for longer routes, which requires planning with third parties. Electrification makes grid capacity important. She noted that electrification is not easy when you are faced with converting a depot which might be more than 50 years old. However, she was feeling ‘good pressure’ to deliver a quiet clean bus service and the first 50-odd electric buses would be coming to Edinburgh in 2024.

Anna Westerberg closed the conference recognising that this big change to electrification had to be managed by operators while continuing to run their day-to-day service. Understanding all the details was the key to getting it right.

This global event had clearly meant a lot to Anna. She finished by saying what a privilege it had been for Volvo to welcome its customers from around the world to share the new World of Volvo centre, the launch of the BZR chassis and the thoughts of Volvo and its partners at this critical time in the bus and coach industry. Routes to net zero, modal shift and zero accidents were Volvo priorities over the coming decade.

These are interesting times. Volvo is about to be 100 years old and CBW will be marking the anniversary – look out for features in the next few weeks.