The first of Aberdeen’s new Wrightbus Streetdeck hydrogen double-deckers was delivered in mid September. Jonathan Welch was given an exclusive first drive

The much awaited arrival of the first Wrightbus hydrogen double-decker for service in Aberdeen finally took place in mid-September, having been delayed for around 12 months as a result initially of the problems at Wrightbus, and latterly as a consequence of the coronavirus pandemic. CBW was invited to have a look around the bus and take it for a drive before its introduction to service later this year, once driver training and other formalities have been completed.

Regular readers will remember that CBW drove the first of Aberdeen’s hydrogen buses in 2014. Those Van Hool A330H buses were part of a trial project, owned by the council and split operationally between First and Stagecoach. That project has now come to an end, but the arrival of the first of these new buses, 39701, heralds not only the start of a longer-term goal but also the entry into service of the world’s first hydrogen-powered double-decker, which brings with it a new set of challenges, not least in the storage of hydrogen which can no longer be on the roof.

I joined First Aberdeen driver trainer Steve Mitchell and Wrightbus Parts & Service’s Warranty and Service Manager Richard Montgomery for a look around the new vehicle before taking it for a short drive around Old Aberdeen. When I arrived, Wrightbus engineers were still working on the bus which has been undergoing mileage accumulation and testing since delivery, and carrying out checks, tests and modifications. After an introductory chat with the engineers, Steve proceeded to show me around the bus as if I were a trainee, highlighting the differences to a diesel bus from a driver’s point of view.

Walk around

Walk around

Our first port of call was the offside rear, where the socket is located to plug the buses in overnight. Whilst these are not battery-electric, and do not need charging, the fuel cell needs to be maintained at its optimum temperature. Steve pointed out that whilst the earlier Van Hools just needed plugging in, the Streetdeck needs the driver or yard staff to push and hold a button once the connection has been made, a green LED signifying that all is well. At present, there are only four charging points available in the depot yard in Aberdeen, with more due to be installed shortly in time for the remainder of the buses arriving. Although located in the same place as for the Van Hools, the charging points are also new.

[…]

By subscribing you will benefit from:

- Operator & Supplier Profiles

- Face-to-Face Interviews

- Lastest News

- Test Drives and Reviews

- Legal Updates

- Route Focus

- Industry Insider Opinions

- Passenger Perspective

- Vehicle Launches

- and much more!

Walking around the bus there is little, other than the graphics, to indicate to the average passenger that this bus is any different. It is finished in Aberdeen’s version of the FirstGroup corporate scheme, featuring the Group’s standard off-white with dark green rear end to reflect the city’s traditional bus colours. At the rear, besides the usual bonnet, the panels between it and the upper deck window are removable to permit access to the six hydrogen tanks which are housed here: at the bottom, where the engine would normally be, is the Ballard fuel cell, with a silver high voltage distribution pack mounted above.

Above this sits a pair of horizontal hydrogen cylinders, mounted transversely across the bus at around head-height, with another pair above those. Further up still are the final two tanks stacked above one another, behind the rear destination screen. There is no lower deck rear window, and a large shelf area below the normal-sized upper deck rear window behind the rear seats accommodates the upper-most tanks.

One notable feature on the outside is the pair of outlet pipes at roof level on the offside rear corner, protected by a stout tree-guard. Although intrinsically safe, hydrogen still attracts comments about the risk of explosion, and Richard pointed out that in the event of an emergency or fire, hydrogen in the system will be automatically vented via these pipes and escape to the atmosphere, making the vehicle safe in seconds. A second purpose of the outlet pipes is to vent the system (but not the tanks!) before the bus is admitted to the workshops.

Stepping inside

Stepping on board, I went to open the cab door and did the same as many others have done, Steve told me, by nearly hitting myself in the face with the upper perspex part, which is significantly longer than the standard lower section. It took a couple of seconds for the significance to sink in, but when seated it is quickly obvious that the design means drivers will not have their view of the nearside mirror impeded by the door frame. As is standard on FirstGroup buses, the nearside mirror is mounted on a short bracket by the door, to prevent the risk of accidents where an extended mirror arm strikes roadside furniture and is knocked off. The upper part of the cab door is fitted with a welcome secondary latch to prevent it rattling when closed.

Technology moves quickly, and the difference between that fitted to the 2014 Van Hools and that on the Streetdeck is noticeable. From a drivers perspective, it has been simplified. This means that driver training should be easier, and problems arising through driver unfamiliarity should be fewer, likely no more than switching to a new type of diesel bus. The overall cab layout will be familiar to drivers of Wrightbus’ Streetlite and Streetdeck products, using the same instrument binnacle and control layout. My impression, without having measured, was that the double-decker features a larger steering wheel, which seems to give a pleasing ‘big bus’ feel.

Simplicity

Starting the bus was simple. Having made sure that we had unplugged it from the depot supply again, the first thing to do was to check that the bus was set to fuel cell (FC) mode, for which there is a switch by the driver’s right hand side. The other option is EV, or electric mode, which is primarily for use by engineers when moving the bus around depots, using solely the on-board batteries.

In pure EV mode, the bus will still function normally and has a range of around 23 miles, meaning that in the event of a fault with the fuel cell it should be able to be driven normally back to the depot. In Aberdeen, the buses will not normally be more than 10 miles away from First’s King Street depot, despite being allocated to one of the city’s furthest-reaching routes, the 19 between Tillydrone, the city centre and the outlying suburb of Peterculter.

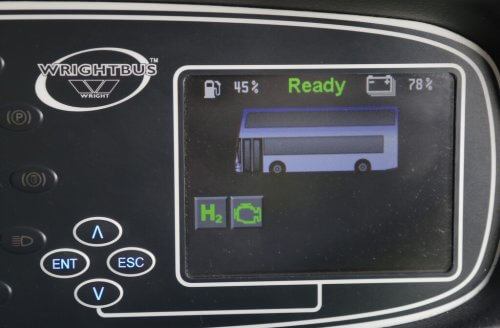

Switching on the master switch immediately brought a disembodied voice informing me that the fire system pressure was OK. The same start button is employed as on the diesel versions: pressing it, I instinctively waited for the engine to start, which brought a laugh from Steve who assures me that I’m not the only one, and even after starting it many times, it still seems strange that nothing appears to happen. A green ‘engine’ symbol appears on the centre console, a logo more commonly associated with a diesel engine management system fault when it appears in yellow, but here in green it signifies that our engine – the fuel cell – is working normally and that we are running on hydrogen. Had we been in EV mode, the symbol would become a green outline instead of a solid colour. In service, the fuel cell may shut down when not needed, and when the bus is running purely on its batteries, the display will show just H2, to signify that the fuel cell is available but not in use.

Getting comfortable

Settling into the cab, I adjusted the standard driver’s seat and set up my mirrors – easy to reach through the adequately-sized sliding cab window. Pedals seemed well-placed and there is a large footrest for the driver’s left foot.

Adjusting the steering wheel led me up against FirstGroup’s policy of the ‘engine’ having to be switched off to allow steering wheel adjustment. Unfortunately, although the switching off and restart process is relatively quick, doing one straight after the other without pausing long enough for the bus to fully shut down upset the electronics and needed to be reset.

Whilst I understand the reasoning behind the feature and realised that time needs to be allowed for the bus to shut down and restart properly, in real-world conditions I can foresee this leading to drivers having the same issue out on the road, such as when they might be in a hurry to take over a late running bus – and something which will do no favours for the acceptance or reputation of the new technology amongst platform staff or passengers.

It must be stressed of course that this is not a fault of the hydrogen bus or the technology itself, and from that point of view the start and shut down procedure is very simple and should cause no problems for drivers in service.

More details

Looking around the cab further, the usual switches are to be found, generally located where a driver would expect them, although I thought that the internal light switches would have been better grouped with the destination screen control unit and heater controls on the angled panel over the steering wheel, rather than horizontally on the ceiling above. On the subject of internal lighting, as is common with diesel buses, the Streetdeck shuts down after a few minutes of ‘idling,’ although this can be overriden by briefly pressing the accelerator. I did however note that it did not seem possible to switch the internal lights back on without switching the fuel cell back on – something which a few manufacturers seem to have overlooked recently, and which means that when sitting at a terminus point in the dark with passengers aboard, the engine must be running to keep the lights on. Less of a problem with a silent hydrogen bus of course, but it is a ‘basic’ which seems to get overlooked in favour of saving power.

Before we headed out on to the public highway, I took the bus for a couple of laps of the depot to get used to the handling. With special permission to exceed the normal 10mph speed limit, we accelerated quickly and smoothly to 25mph before I took my foot off the pedal. The bus will regenerate energy when slowing down, and when I lifted off the throttle I found the rate of deceleration was good and not too severe, the bus coasting smoothly until I touched the brakes to bring us to a stop. When Richard Sharman drove Oxford Bus Company’s Daimler OM934-engined version not long ago for CBW, he felt that the brakes were not as powerful as he expected they would be, and with this in mind I pressed the pedal firmly. I am happy to report I quickly discovered that that was not the case here; the brakes felt powerful and progressive. To indicate to the driver that energy is being recovered from braking, the rear wheel of the bus graphic on the dashboard turns blue.

Simplification

Another welcome change compared to the earlier Van Hool buses is that there is no separate retarder control, everything on the Streetdeck being controlled via the brake pedal. Different drivers will have different preferences, and whilst I found no problem doing most of the braking with my right finger on an A330H, on which the retardation alone was powerful and usable down to walking pace, it has to be said that the Wrightbus solution makes it much easier for drivers to switch between different vehicle types without the worry of unfamiliarity or confusion.

As with diesel models of the Streetdeck and Gemini 3, operation of items such as doors and wipers was easy and all functions seemed to work well. Steve told me that on colder mornings, the bus heats up quickly, taking around just 10 minutes for the cab and saloon to start feeling warm, which drivers will appreciate on bitterly cold Scottish mornings. This highlighted one advantage of hydrogen over pure electric, where the latter uses up a proportion of its valuable traction power for heat and light, especially in winter. Demisters and blowers seemed up to the job, again being the same as on the bus’ diesel cousins.

Interior

Looking around the saloon, it is finished in FirstGroup’s standard pastel colours with bright pink handrails. Apart from the shelf behind the rear seats, which takes up the equivalent of one row of seating, the 40-seat upper deck is similar to other vehicles in First’s fleet.

Downstairs, the need to house equipment and batteries means that there are 12 forward-facing seats and eight which face rearwards, though they are arranged neatly to give four bays of four seats at the rear. Two additional pairs of forward-facing ones immediately behind the wheelchair and standee space are the only four fixed seats in the immediate low-floor, along with five tip-up seats.

On both decks, the rear seat consists of four wider seats instead of the usual five narrow ones, a feature which passengers will no doubt welcome; although at busy times the capacity is marginally reduced, the centre rear seat is often not used as it can be quite cramped or for fear of being thrown forwards in an emergency, so this seems a sensible move.

A pleasing feature was the low-level stair lighting, with individual lights on the side wall above each tread, making more of a feature of the straight staircase. A useful if small ticket bin is provided in the side panel of the staircase, a feature sometimes neglected. The cove panels on both decks feature air vents from which a steady stream of fresh air helps maintain the saloon temperature, whilst a number of hopper windows allow for extra ventilation.

On the road

Having taken the bus around the yard, we headed out of the depot to see how the bus handled and felt on the open road. I have to say that I was impressed. I had noted when I first started driving that the steering was slightly heavier than I had expected – but by no means was it too heavy, and had a good amount of feel and feedback.

I deliberately took the bus down one of the city’s more attractive bus routes, along the cobbled streets of Old Aberdeen. With Richard at the wheel here, I took the opportunity to get some drive-by video shots for CBW’s YouTube channel as we passed through the historic University of Aberdeen campus. In fairness, although the undulating cobbled surface provoked some bodywork noise, this had to be expected on the rough surface and on smoother tarmac roads I could neither see nor hear any issues with the build quality or fit of interior parts during our short trip.

The dashboard is uncluttered but provided all the information I needed, the speedometer being easily visible to the left whilst the digital screen showed the amount of hydrogen remaining in the tanks along with remaining battery charge. Above the driver, a useful pair of screens provide a view of both the top deck and a welcome view down the stairs, whilst a mirror gave a good view of the lower saloon, the usual issue of refection notwithstanding.

Another welcome feature was the small sliding window built in to the cab door, allowing the driver to pass things such as timetables to passengers without having to open the whole door.

These buses being for Aberdeen, they are fitted with First’s standard autofare equipment, the vault being mounted below the dashboard, with glass-backed hopper above. Stopping at an imaginary bus stop, I did notice that this seemed to place the Ticketer ticket machine somewhat far away, and whilst it was well-located for passengers taking or scanning tickets, it seemed that even with the very adjustable arm at full stretch it would be a bit of a reach for drivers. It is difficult to see how the Ticketer machine could have been mounted closer without a full redesign of the dashboard and still give the driver a view of the hopper, although I’m sure that it would not be beyond the realms of possibility that a longer arm could be fitted to the ticket machine. Naturally this would be the same on the diesel version. When pulling away from the same imaginary bus stop, I was pleased to note that the automatic brake (which comes on when the doors are opened) released smoothly as I pressed the accelerator.

Plenty of power

General handling seemed good. From both a driver’s and passenger’s point of view the ride was smooth and very quiet, with just the whining of the motor propelling us along to be heard. The smooth, gear-free acceleration makes for a safer, more comfortable journey, and I found that the bus had ample torque and power to be able to pull away into moving traffic or at a busy junction and pick up speed quickly, and power delivery was easily controllable. Time prevented us from heading out of town onto faster roads: I am told the bus drives well at higher speeds.

It was interesting to note that whilst I was taking photographs around the university, a number of students noticed the branding and commented on the bus and it’s zero-emissions credentials as they walked past. Although not via the same route as we took, the buses will be serving the University of Aberdeen when operating on route 19, for which the majority will be branded with a turquoise front, and which will see them pass by the equally modern and turquoise university library along Bedford Road.

A trip into the city centre gave me another chance to jump off and take some pictures, Richard again doing the honours driving the bus past Aberdeen’s impressive Marischal College. Marischal College is said to be the second largest granite building in the world after Spain’s El Escorial. It is now the home of Aberdeen City Council, a key partner in the hydrogen bus projects and which operates a number of other hydrogen-powered vehicles. In recent years, this street has become pedestrianised, with access for buses only and restricted over the short stretch to walking speed.

Gong gone

Unlike the Van Hools, these buses are not fitted with a pedestrian gong, nor any white noise generator to warn pedestrians or the visually-impaired of their approach. A pedestrian-friendly gong or bell sound would seem an obvious addition to all electric or hydrogen buses, giving drivers the option to sound a more friendly and less obtrusive warning of their presence than resorting to the horn.

Having returned to the depot and parked the bus where it could be plugged in again, I spoke a little more to Steve and Richard about the new buses. “They’re really nice and smooth,” Steve said, echoing my own experience so far. “The field of vision is improved for the driver and passengers will appreciate that there’s a lot more space for buggies and wheelchairs. From a training perspective it is good that they have simplified everything. We are proud to have the first hydrogen double-deckers in the world. It’s been fantastic working with the guys from Wrightbus, and we’re looking forward to seeing them out on the road soon.”

Richard added: “We’re delighted with the performance so far. We’re excited to have the partnership with Ballard and ZF in this venture, it has all been very well received so far, by First and Aberdeen City Council. We look forward to a long and successful partnership delivering reliable and environmentally-friendly transport and a first class passenger experience.”

Conclusions

Having both driven and ridden on the bus, my impressions were overwhelmingly positive. The vehicle itself seemed well built and engineered, and the enthusiasm and knowledge of the Wrightbus staff as well as those at First Aberdeen showed the pride and commitment to the project.

It might be seen as a little unfair to compare with the older technology, but I think the comparison is a valid one as those on the ground will be judging by the same criteria. Whilst the A330Hs that kicked off the project were good buses, they felt (in the UK market at least) like outsiders and a very bespoke product. The Streetdeck feels like a bus that fits in much better with UK operators’ needs, and will prove much less challenging and more economical to operate as part of a mixed fleet with diesel vehicles. As these and further vehicles for cities including London and Birmingham come on-line, they look set to both help normalise the technology in everyday use and continue to reduce the unit price as more are placed into service. See more at: www.youtube.com/c/CoachBusWeek