ENERGY

Bramble Energy is the lead partner of a project with Equipmake, Aeristech, and the University of Bath to develop lower-cost printed circuit hydrogen fuel cells

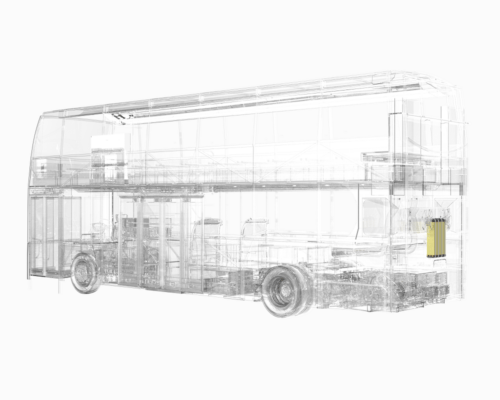

Hydrogen fuel cell specialist Bramble Energy has joined forces with Equipmake, Aeristech and the University of Bath to develop a hydrogen double-deck bus integrating Bramble’s new low-cost printed circuit board fuel cell (PCBFC) technology. Bramble is the lead partner of the Hydrogen Electric Integrated Drivetrain Initiative (HEIDI) which has received £6.3m funding from the Advance Propulsion Centre as part of its Automotive Transformation Fund, which will be matched by industry to a total of £12.7m.

The UK-based consortium will develop a hydrogen-powered double-decker, using what it says is a first-of-its-kind fuel cell technology from Bramble Energy alongside Aeristech’s high efficiency air compressor and Equipmake’s motor power electronics and battery management system. The powertrain will be optimised through vehicle simulations carried out by the University of Bath.

Bramble Energy has developed a patented printed circuit board technology which it says allows it to create bespoke fuel cell stacks in a matter of days at scale and low-cost as it eliminates the requirement for a number of complex and costly components found in a typical electrochemical stack, which not only simplifies the supply chain but also does not require vast retooling for manufacture.

The fuel cell stacks can be produced in almost any size and arrangement according to the end customer’s needs, resulting in what the company says is an unparalleled cost-effective solution to supporting and accelerating the decarbonisation of public transport and to improve air quality in towns and cities around the world.

CCO at Bramble Energy Dr Vidal Bharath commented: “Fuel cell technology can deliver a viable net zero solution that lends itself to commercial vehicles where downtime needs to be limited. This consortium of partners means that we will be able to deliver a world-leading hybridised powertrain, utilising our innovative low cost PCBFC technology for the bus sector, where there needs to be a viable electrified solution that can deliver on cost and scalability.”

In support of ambitions to build an end-to-end supply chain for zero-emission vehicles (ZEVs) in the UK, the project is expected to support nearly 500 jobs over the next decade and save nearly 6 million tonnes of CO2 from being emitted. The UK-based consortium in the HEIDI project will support fuel cell manufacturing in the UK for buses and commercial vehicles and accelerate the cost reduction of fuel cells and their use.