Repowering buses can bring big benefits, says John Lewis

Cascaded down through fleets and relocated from busy city centres to quieter rural districts, buses can have a long shelf life.

A possible cause of early termination however is the power source they use; Euro 3, Euro 4 and even Euro 5 diesels may be viewed as increasingly unacceptable by local authorities worried about the impact NOx and particulate emissions are having on the environment. Those pollutants

can contain un-burnt hydrocarbons and carbon monoxide.

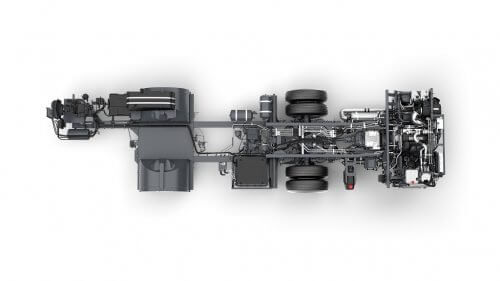

So does that mean that whole swathes of single and double-deckers will have to be scrapped? Not necessarily – one option could be to remove that old, polluting and uneconomical diesel engine and replace it with something younger, cleaner and potentially more efficient.

That something could be a fully-electric drivetrain, suggests Magtec. As well as supplying such drivetrains on an OE basis – to Optare for example – the Yorkshire-based company can install them in existing buses as a retrofit.

Simon Buckley, Magtec Programme Manager, said: “We estimate that operators should see a payback in five years. We’ve done work in the USA and Africa as well as in the UK, including sight-seeing double-deckers in operation in York. We’ve repowered hybrids as well as diesels.”

Benefits of the retrofit include zero tailpipe emissions with annual environmental savings of 535kg of NOx and 33 tonnes of CO2, so far as a city bus is concerned, says the firm.

With no diesel engine or conventional gearbox, maintenance costs are down by as much as two-thirds according to Magtec. Switching from diesel to electricity should result in a yearly fuel expenditure saving of roughly £20,000, it calculates. “The latest 300kWh batteries we’re using can offer a range of between 160 to 180 miles on a single charge,” Simon continued. “It takes six hours to recharge the battery pack and typically that will be done overnight.”[…]

By subscribing you will benefit from:

- Operator & Supplier Profiles

- Face-to-Face Interviews

- Lastest News

- Test Drives and Reviews

- Legal Updates

- Route Focus

- Industry Insider Opinions

- Passenger Perspective

- Vehicle Launches

- and much more!