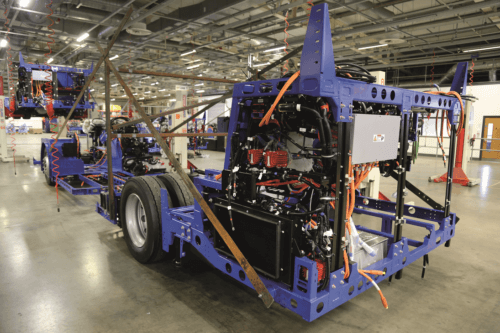

Could hydrogen coaches be on the cards? Jonathan Welch continues his tour of the Wrightbus factory

In the last issue, we looked at how Wrightbus has fared since its rescue from administration by Jo Bamford’s Bamford Bus Company, and how it has set about reshaping itself from a relatively traditional bus builder to one which is spearheading the drive to hydrogen power, as well as competing in the battery electric bus segment. We continue our factory visit and our conversation with CEO Buta Atwal, Development and Manufacturing Director Damian McGarry, Chief Commercial Officer Ben Werth and AllServiceOne Service Director David Murdoch to find out what the company has in store for the future, including hydrogen coaches and its new AllServiceOne offshoot, which broadens the range of services available under the same roof.

Hydrogen coaches

“Most of us understood that we had a good solid business,” explained Damian, talking about the fall into administration and subsequent rescue. “But it was affected by market volatility and other effects. The fundamentals were there, and we just needed to reposition in size and agility to meet market needs.”

[…]By subscribing you will benefit from:

- Operator & Supplier Profiles

- Face-to-Face Interviews

- Lastest News

- Test Drives and Reviews

- Legal Updates

- Route Focus

- Industry Insider Opinions

- Passenger Perspective

- Vehicle Launches

- and much more!